SUPSI launches demonstration activity of its didactic Mini-Factory with the GRETA tool

By Riccardo Canavesi, SUPSI

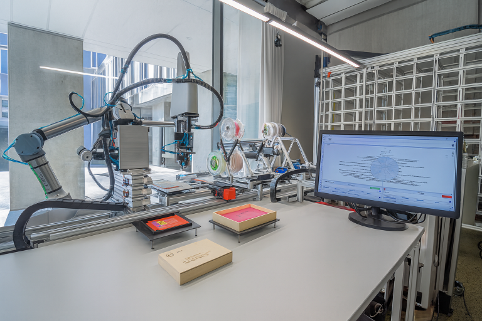

The University of Applied Sciences and Arts of Southern Switzerland (SUPSI) started the demonstration activities of its didactic Mini-Factory by implementing its own developed software: GRETA. The Mini-Factory is a smart automated system that assembles customized coffee mugs, designed to showcase flexible, modular, and sustainable manufacturing solutions.

Its mission is based on four key principles: (i) modularity, with flexible automation enabling resilience and reconfiguration; (ii) integration, ensuring interoperability among technologies from different vendors; (iii) innovation, validating the efficiency and scalability of Industry 4.0 solutions; and (iv) customizability, demonstrating the ability to adapt to evolving customer requirements.

Through the implementation and deployment of GRETA tool, the Mini-Factory will now serve not only as a technological testbed but also as a living laboratory for sustainability assessment. This will make it possible to exploit all GRETA’s functionalities, from data monitoring to performance evaluation, and to demonstrate how digital tools can drive more sustainable, innovative, and adaptive production models. GRETA is just a small piece of the entire puzzle: the full DaCapo framework (Modular Digital Threads, Middleware, Dashboard and Digital Product Passport) will be deployed in the Mini-Factory, enabling a wide exploitation of the project results.