CE-DSS: The intelligence layer developed by CORE IC that elevates PESMEL’s warehouse operations

By Christina Vlasi, CORE Innovation Centre (CORE IC)

From data to decisions, intelligence is the new engine of industrial sustainability.

At the center of this transformation stands PESMEL’s Circular Economy Decision Support System (CE-DSS), developed by CORE Innovation Centre (CORE IC) — a next-generation intelligence tool that turns complex data into clear, sustainable decisions. By combining predictive analytics, digital twins, and advanced monitoring, the CE-DSS helps operators coordinate every dimension of warehouse performance: managing assets efficiently, extending equipment life, and minimizing energy consumption.

The CE-DSS connects and harmonizes data from multiple sources — including PESMEL’s Warehouse Management System (WMS) and other advanced analytical tools developed within the DaCapo project — to ensure that every maintenance plan, task schedule, and motion configuration works together in perfect alignment.

The CE-DSS doesn’t simply support decisions — it enables intelligent coordination, helping warehouses evolve from automated systems into adaptive ecosystems that operate according to the circular economy principles of Repair and Reduce.

The 3 functionalities of the PESMEL CE-DSS

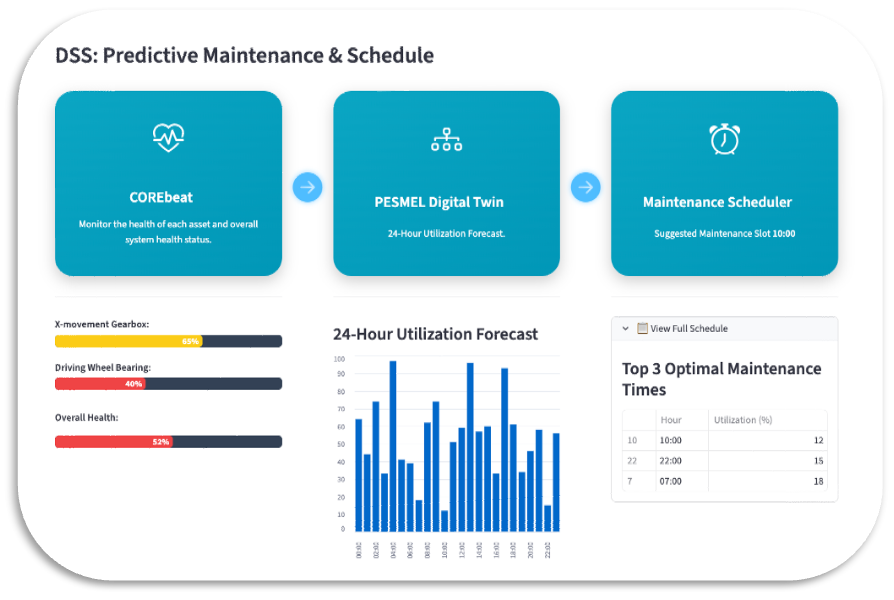

Predictive Maintenance & Scheduling — Powered by COREbeat

Within the DaCapo project, COREbeat, a cutting-edge predictive maintenance platform, plays a pivotal role in advancing sustainable manufacturing, by predicting failures, optimizing maintenance and improving production efficiency.

Developed by CORE Innovation Group, COREbeat is continuously enhanced through pilot applications and experimental deployments led by CORE Innovation Centre within European research projects such as DaCapo.

In the PESMEL use case, COREbeat continuously monitors and diagnoses the health of key stacker crane components - including the X-movement gearbox, driving wheel bearings, and the crane’s overall structural integrity.

When anomalies or early wear patterns are detected, COREbeat feeds this data into the CE-DSS, which uses PESMEL’s Digital Twin (DT) simulations for utilization to provide an optimal maintenance schedule. Through this, the system minimizes disruption, downtime, and the risk of equipment failure.

Key Impact: minimal downtime, extended equipment life, and resource-efficient maintenance.

Predictive Maintenance and Scheduling Functionality of the CE-DSS

System Status & Forecasting — Turning Data into Foresight

An important functionality of the CE-DSS focuses on real-time system awareness and predictive foresight. Fully connected to the PESMEL WMS, it continuously gathers live data on workload, task priorities, and key performance indicators.

Using this input, the CE-DSS activates the Hurry Factor tool, which forecasts the urgency level of specific warehouse tasks. This allows operators to focus on what matters most — before it becomes critical.

By predicting task urgency and evolving workload conditions, the CE-DSS gives operators early insight into where operational attention will soon be required. These forecasts are displayed through intuitive dashboards that visualize status, workload balance, and process trends at a glance.

Key Impact: Operators shift from reactive management to proactive decision-making — anticipating challenges instead of chasing them.

Systems Status and Forecasting Functionality of the CE-DSS

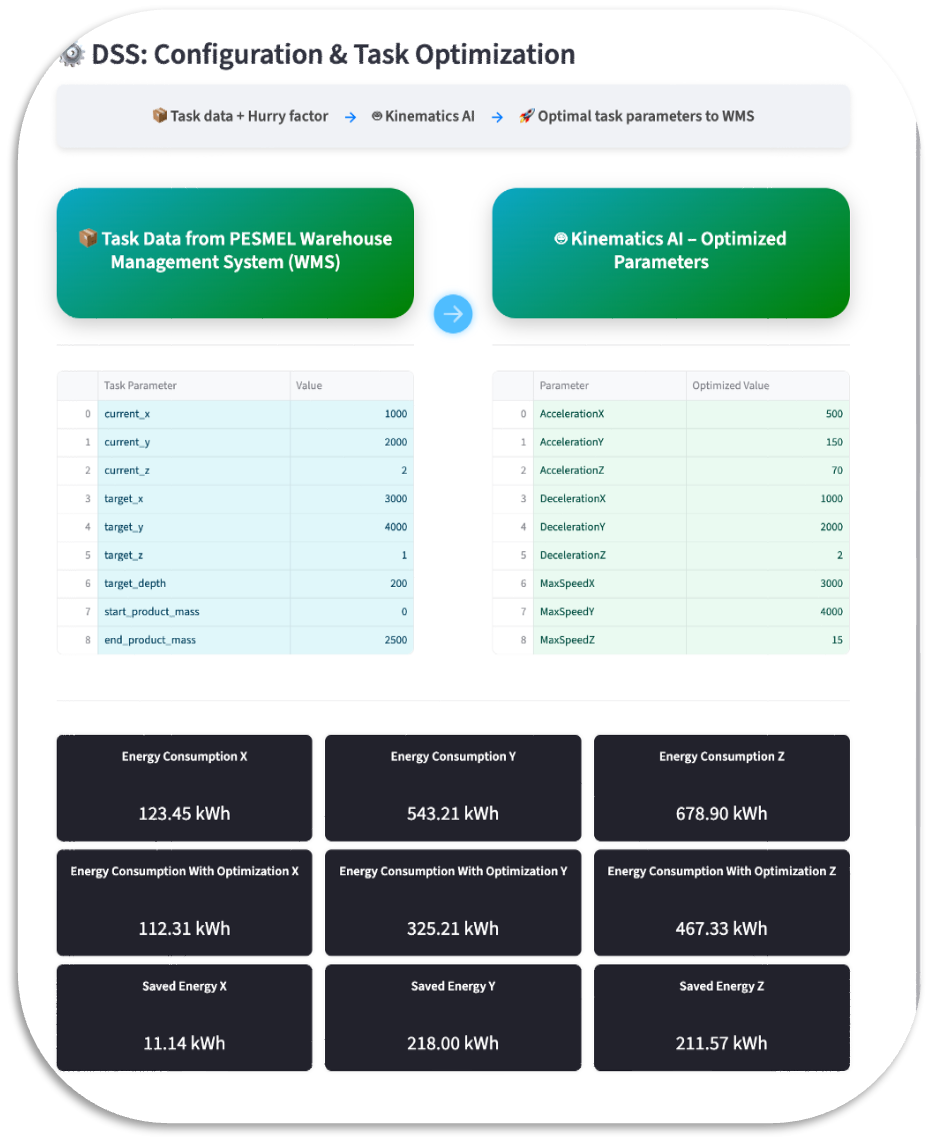

Configuration & Task Management — Efficiency in Motion

The last functionality of the PESMEL CE-DSS turns intelligence into tangible energy savings. By combining WMS task data with urgency forecasts, the CE-DSS determines how to execute crane operations in the most efficient way possible.

Connected with the Kinematics AI tool, the CE-DSS provides the WMS with optimized parameters — including acceleration, deceleration, and maximum speed for each crane axis. This ensures every movement is carried out with the lowest possible energy consumption, while maintaining precision and throughput.

Operators can visualize crane movements, energy usage, and workload distribution directly through the CE-DSS interface — ensuring total transparency and control.

Key Impact: Reduced energy demand, smoother operation, and extended maintenance intervals through intelligent coordination.

Configuration and Task Optimization Functionality of the CE-DSS

From Data to Circular Intelligence

The PESMEL CE-DSS is far more than a tool — it is the strategic intelligence layer that transforms modern warehouses into adaptive, self-optimizing ecosystems. By combining predictive maintenance, real-time operational foresight, and energy-efficient task optimization, the CE-DSS ensures that every operational decision advances efficiency, sustainability, and reliability.

In doing so, it brings the circular economy to life: reducing resource use, extending equipment lifespan, and minimizing energy consumption — all while maintaining peak performance.

With the CE-DSS at its core, a warehouse is no longer simply automated — it becomes aware, adaptive, and resilient, shaping the future of sustainable industrial operations.