DaCapo will demonstrate its commercial and replicability potential on high-impact applications in critical EU manufacturing sectors: aeronautics, smartphones (ICT & consumer electronics), and warehousing (logistics, including construction).

Use Cases

Use Case 1

Extending sustainable manufacturing and repairability approaches for aeronautic value chains

GKN Aerospace supplies advanced aerospace systems, components, and technologies. The focus of the production relies on engine components, airframe structures or fuselage structures. GKN Engine Systems designs, develops, manufactures, assembles and maintains engine and rocket components for both commercial and military applications.

Critical Materials addressed: Titanium alloys (Ti 6-4)

Product lifecycle addressed stages: Engineering, Manufacturing, Use phase

Enabled Circular Economy Strategies: Reduce, rework/remanufacture and repair/refubrish

Use Case 2

Eco-design, diagnosis and maintenance for modular mobile phones

FAIRPHONE BV was founded in 2013 to face the social and environmental challenges of the electronics industry by providing the market with a sustainable smartphones alternative. It addresses the “make-use-dispose” trend with modular smartphones (separate functional modules are combined) that are durable and easy to repair.

Critical Materials addressed: Smartphones components raw materials: Co, Au, Li, W, Ag, rare earths.

Product lifecycle addressed stages: Design, Engineering, Use phase, EoL.

Enabled Circular Economy Strategies: Reduce, repair/refurbish, reuse and recycle.

Use Case 3

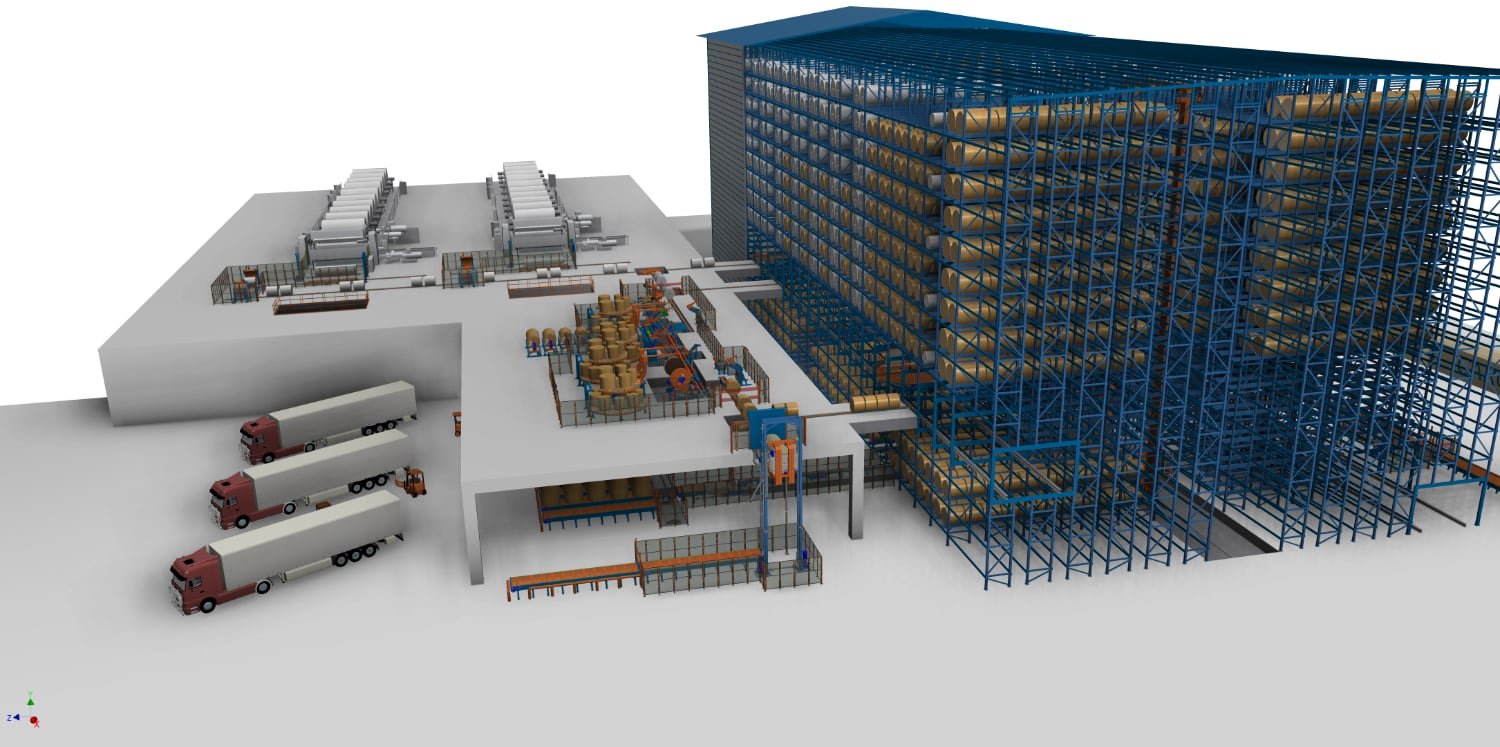

R-cycles in material flows for warehouse design, construction and operation

PESMEL delivers solutions that integrate and streamline material flows and logistics of manufacturing facilities in pulp & paper, metal, and tire industries.

Critical Materials addressed: Warehouse construction and equipment components: Al, ICT components etc.

Product lifestyle addressed stages: Design, Engineering, Use phase, EoL

Enabled Circular Economy Strategies: Reduce, repair/refurbish, reuse and recycle.

Production environment and didactic factories

Technologies

DaCapo aims to address the technical challenges that CE adoption imposes on manufacturing value chains and overcome market barriers mainly: i) the workforce skill shortage regarding the adoption of new advanced digital tools and services, and ii) the lack of awareness, trustworthiness and risk-aversion of end users to new digital technologies adoption.

DaCapo de-risking approach will be twofold:

1

Deploying a Didactic Factories (DF) Network consisting of open accessible pilot facilities hosted at the RTOs (each RTO is a network node) available for the EU manufacturing sector. This Network will be an orchestrated effort in giving access to test and validation facilities and a common training framework (methodology, materials and tools) based on

in-situ training and access to latest technologies.

2

Deploying a complete replicability boosting strategy focused on lowering market acceptance barriers through supplementary actions (standardisation, products certification, guidelines, technology assessment, benchmarking, showroom and Open Science practices), increasing DaCapo commercialisation opportunities.