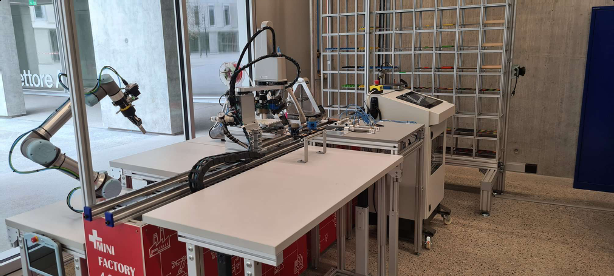

SUPSI Mini Factory 4.0

SUPSI - Scuola universitaria professionale della Svizzera italiana, SPS lab, Viganello, Switzerland

The Mini-Factory is an advanced, fully automated IIoT production and assembly system that bridges hands-on learning with industrial innovation. It’s a unique platform where students, professionals, companies, and innovation managers can explore and test smart manufacturing solutions in a real-world setting. Designed for flexibility and resilience, the Mini-Factory can handle both customised, on-demand production and stock-based workflows. It features state-of-the-art technologies, including a vertical warehouse, Cartesian and SCARA robots, RFID systems, laser triangulation sensors, 3D printing modules, and a collaborative robot cell — all coordinated through PLC and HMI systems and integrated within a Digital Twin environment. This modular and reconfigurable setup enables rapid prototyping, process optimisation, and experimentation with human-machine collaboration and data-driven automation. Whether for training, research, or industrial co-development, the Mini-Factory provides a cutting-edge environment to experience the future of manufacturing today.

-

D - Decision support through real-time IIoT data, predictive analytics, and LCA/Circular Economy evaluations using StarDust and GRETA

R - Data-driven modelling, simulation, and digital twin of smart manufacturing scenarios using Arena and IIoT-integrated monitoring tools

B - EU, national, regional project development on circular economy in the manufacturing sector

E - Strategic visioning, impact assessment, and ecosystem engagement for SMEs and industrial partners

S - N/A

T - Technology testing, PoC development, small-series prototyping, and product demonstration in a fully operational pilot line -

The GRETA Impact Assessment Tool is designed to evaluate the environmental, social, and economic impacts of products manufactured within the SUPSI Mini-Factory. It leverages data collected through the Modular Digital Thread (MDT) to perform real-time Life Cycle Assessment (LCA) and circularity evaluations. Results are stored in the middleware and displayed via the Digital Product Passport (DPP), enabling transparent and data-driven decision-making. The tool supports students, researchers, SMEs, and innovation managers in understanding and optimizing product sustainability from design to production.